Dive into the world of advanced nonwoven textile technologies, where traditional methods meet modern innovations to shape industries and drive sustainability. Get ready for a fascinating journey through the evolution, advantages, and latest trends in nonwoven textiles.

Introduction to Advanced Nonwoven Textile Technologies

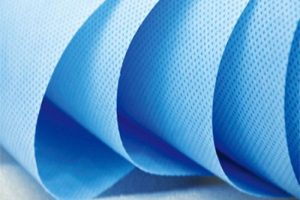

Nonwoven textiles are fabrics made by bonding or interlocking fibers without weaving or knitting. They are significant in various industries due to their versatility, cost-effectiveness, and unique properties such as breathability, water resistance, and durability.The evolution from traditional textile manufacturing to advanced nonwoven technologies has revolutionized the textile industry. Advanced nonwoven technologies involve processes like meltblowing, spunbonding, and needle punching, which offer superior strength, flexibility, and efficiency compared to traditional methods.

Applications of Advanced Nonwoven Textiles

- Medical and Healthcare: Advanced nonwoven textiles are used in surgical gowns, face masks, wound dressings, and disposable medical supplies due to their hygienic properties and ability to block pathogens.

- Automotive: Nonwoven textiles are preferred in car interiors, upholstery, and filtration systems for their lightweight, noise reduction, and insulation capabilities.

- Geotextiles: In civil engineering, nonwoven textiles are used for erosion control, drainage, and soil stabilization due to their high tensile strength and permeability.

- Packaging: Nonwoven textiles are used in packaging materials like shopping bags, protective covers, and agricultural packaging for their tear resistance and recyclability.

Types of Advanced Nonwoven Textile Technologies

Nonwoven textiles are produced using various advanced technologies that offer unique characteristics and properties. Let’s explore different types of advanced nonwoven textile technologies such as spunbond, meltblown, and needlepunch.

Spunbond Technology

Spunbond technology involves extruding continuous filaments of a polymer, such as polypropylene or polyester, which are then laid down on a conveyor belt to form a web. The web is bonded together using heat and pressure. Spunbond nonwovens are known for their strength, durability, and breathability. Examples of products made using spunbond technology include disposable medical gowns, agriculture covers, and geotextiles.

Meltblown Technology

Meltblown technology utilizes high-velocity air to blow molten polymer through fine nozzles, creating microfibers that are randomly deposited on a collecting belt. The fibers are then bonded together by heat or pressure. Meltblown nonwovens are characterized by their fine fiber diameter, high filtration efficiency, and softness. Products made using meltblown technology include surgical masks, air filters, and wipes.

Needlepunch Technology

Needlepunch technology involves punching barbed needles through a web of fibers to entangle and interlock them. This mechanical process creates a nonwoven fabric with excellent strength, resilience, and abrasion resistance. Needlepunch nonwovens are used in automotive interiors, carpets, and geotextiles due to their durability and dimensional stability.

Advantages of Advanced Nonwoven Textile Technologies

Advanced nonwoven textile technologies offer a plethora of advantages over traditional woven textiles, making them a popular choice in various industries. Let’s explore some of the key benefits:

Cost-Effectiveness

Advanced nonwoven textiles are cost-effective due to their efficient production process, which involves minimal waste and labor. The use of synthetic fibers in nonwoven textiles also contributes to their affordability, making them a more economical choice compared to traditional woven textiles.

Durability

One of the standout features of advanced nonwoven textiles is their exceptional durability. These textiles are highly resistant to wear and tear, making them ideal for applications that require long-lasting performance. Whether used in medical products, automotive components, or filtration systems, advanced nonwoven textiles can withstand harsh conditions without compromising on quality.

Efficiency

Advanced nonwoven textile technologies offer superior efficiency in terms of production speed and versatility. With the ability to be customized for specific applications, nonwoven textiles can be tailored to meet the exact requirements of different industries. This versatility allows for the creation of lightweight, breathable fabrics that offer optimal performance in various settings.

Sustainability and Environmental Conservation

In today’s environmentally-conscious world, the sustainability of materials is a crucial factor to consider. Advanced nonwoven textile technologies contribute to sustainability by reducing the carbon footprint associated with textile production. The efficient manufacturing process of nonwoven textiles consumes less energy and resources compared to traditional woven textiles, making them a greener alternative. Additionally, the recyclability of nonwoven textiles further promotes environmental conservation by reducing waste and minimizing the impact on landfills.Overall, the advantages of advanced nonwoven textile technologies in terms of cost-effectiveness, durability, efficiency, and sustainability make them a versatile and eco-friendly choice for a wide range of applications.

Innovations and Trends in Advanced Nonwoven Textile Technologies

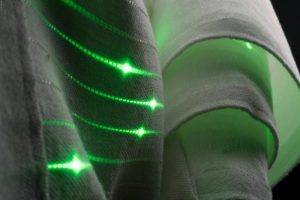

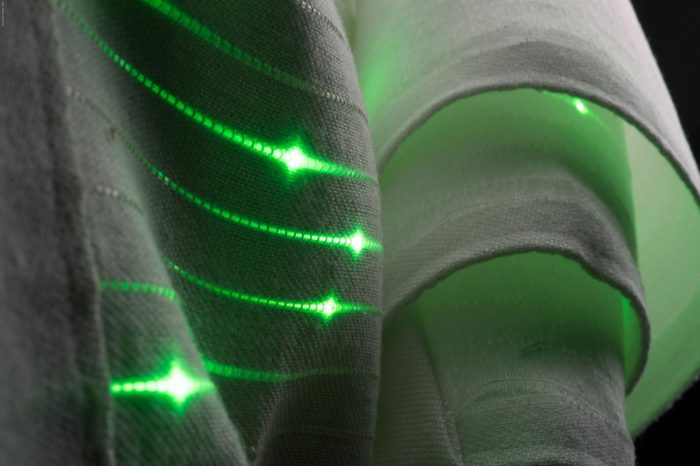

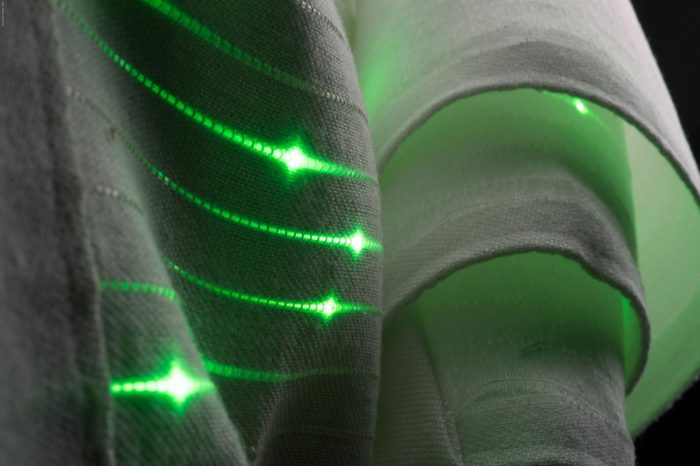

Nanofiber Production and 3D Printing are revolutionizing the field of advanced nonwoven textile technologies, paving the way for exciting innovations and trends that are shaping the future of various industries. These advancements are not only driving research and development but also opening up new possibilities in the textile industry.

Nanofiber Production

Nanofiber production involves the creation of extremely tiny fibers with diameters in the nanometer range. These nanofibers offer unique properties such as high surface area-to-volume ratio, exceptional strength, and enhanced filtration capabilities. The production methods for nanofibers include electrospinning, self-assembly, and melt blowing. Nanofiber technology is being widely adopted in industries like filtration, healthcare, and protective clothing due to its superior performance.

3D Printing in Nonwoven Textiles

D printing has found its way into the nonwoven textile industry, enabling the fabrication of complex structures and customized products. This additive manufacturing process allows for the creation of intricate designs and patterns that were previously challenging to achieve with traditional methods. 3D printing in nonwoven textiles is being explored for applications in fashion, automotive, and medical sectors, offering endless possibilities for innovation and creativity.

Current Trends in Advanced Nonwoven Textile Technologies

The current trends in advanced nonwoven textile technologies indicate a shift towards sustainable and eco-friendly practices. Manufacturers are increasingly focusing on developing biodegradable and recyclable nonwoven textiles to reduce environmental impact. Moreover, there is a growing demand for smart textiles integrated with sensors and electronics for interactive functionalities. These trends are driving the industry towards creating innovative solutions that meet the evolving needs of consumers and industries.

TEXTILES AND NONWOVENS

In the world of fabrics and materials, textiles and nonwovens play a crucial role in various industries. While both serve similar purposes, they differ in terms of manufacturing processes and applications.

Manufacturing Processes and Applications

Textiles are traditionally made through weaving, knitting, or crocheting yarns together to form a fabric. On the other hand, nonwovens are created by bonding fibers together using mechanical, chemical, or thermal processes, without the need for weaving or knitting. This makes nonwovens more cost-effective to produce and allows for a wider range of fiber types to be used.

- Textiles are commonly used in clothing, home furnishings, and industrial applications where durability and flexibility are key.

- Nonwovens, with their versatility and ease of production, find applications in healthcare (such as surgical masks and wipes), automotive (as insulation and filtration materials), and geotextiles (for erosion control and drainage systems).

Properties Comparison

When it comes to properties, textiles and nonwovens exhibit different characteristics in terms of strength, flexibility, and breathability.

- Textiles are known for their strength and durability, making them suitable for heavy-duty applications like upholstery fabrics and tents.

- Nonwovens, while not as strong as traditional textiles, offer flexibility and adaptability that make them ideal for disposable products like diapers and medical gowns.

- In terms of breathability, textiles allow for better air circulation due to their woven structure, whereas nonwovens can be engineered to provide specific levels of breathability depending on the application.

Role in Specific Sectors

Nonwoven textiles play a crucial role in specific sectors such as healthcare, automotive, and geotextiles, each with unique requirements and applications.

- In healthcare, nonwoven fabrics are used extensively for medical masks, surgical gowns, and wound dressings due to their disposable nature and ability to provide a barrier against contaminants.

- In the automotive industry, nonwovens are used for interior upholstery, insulation, and filtration to enhance comfort, reduce noise, and improve air quality inside vehicles.

- Geotextiles made from nonwoven materials are employed in civil engineering projects to reinforce soil, prevent erosion, and provide drainage solutions, showcasing the versatility and durability of nonwoven textiles in infrastructure development.

Closing Summary

In a nutshell, advanced nonwoven textile technologies offer cost-effective, durable, and eco-friendly solutions across various sectors, paving the way for a sustainable future in the textile industry. Stay ahead of the curve with these cutting-edge advancements!

Popular Questions

What makes advanced nonwoven textiles different from traditional woven textiles?

Advanced nonwoven textiles are known for their cost-effectiveness, durability, and efficiency compared to traditional woven textiles.

How do advanced nonwoven textile technologies contribute to sustainability?

These technologies contribute to sustainability by reducing waste, energy consumption, and environmental impact in manufacturing processes.

What are some key applications of advanced nonwoven textiles?

Advanced nonwoven textiles are preferred in sectors like healthcare, automotive, and geotextiles due to their unique properties and performance.