Step into the world of Nonwoven fabric types and uses where innovation meets functionality in a seamless weave of knowledge and creativity. From versatile materials to practical applications, this topic promises to unravel a tapestry of insights that will leave you hooked and intrigued.

Get ready to explore the intricacies of nonwoven fabrics and discover the endless possibilities they offer across various industries.

Nonwoven Fabric Types

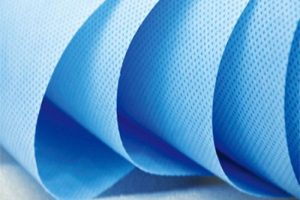

Nonwoven fabrics are versatile materials that are produced directly from fibers rather than being woven or knitted together. There are several types of nonwoven fabrics, each with unique characteristics and uses.

Spunbond Nonwovens

Spunbond nonwovens are made by spinning continuous filaments of polypropylene or polyester into a web-like structure. They are known for their strength, durability, and breathability. Spunbond nonwovens are commonly used in applications such as disposable medical gowns, agriculture covers, and geotextiles.

Meltblown Nonwovens

Meltblown nonwovens are produced by melting polymer granules and extruding them into fine fibers, which are then laid down to form a nonwoven fabric. These fabrics are characterized by their high filtration efficiency, making them ideal for use in face masks, air filters, and oil absorbents.

Needle-Punched Nonwovens

Needle-punched nonwovens are created by mechanically interlocking fibers through a needle-punching process. This method results in a fabric that is strong, resilient, and abrasion-resistant. Needle-punched nonwovens find applications in automotive interiors, carpet backing, and insulation materials.Overall, spunbond nonwovens are preferred for their strength, meltblown nonwovens for their filtration properties, and needle-punched nonwovens for their durability and resilience in various applications.

Nonwoven Fabric Production Process

Nonwoven fabrics are manufactured through a unique process that involves the bonding of fibers together without weaving or knitting. This method results in a versatile material with various applications in different industries.

Methods of Creating Nonwovens:

- Spunbonding: This method involves extruding continuous filaments of a polymer, which are then stretched and bonded together to form a nonwoven fabric.

- Meltblown: In this process, high-velocity air jets are used to blow melted polymer onto a conveyor, creating a fine fiber web that is then bonded to form a fabric.

- Needle Punching: Fibers are mechanically entangled using barbed needles, creating a strong and durable nonwoven fabric.

Overview of Equipment Required:

- Extruders: Machines used to melt and extrude polymer into filaments for the spunbonding process.

- Air Jets: Equipment necessary for the meltblown method to blow melted polymer onto a conveyor.

- Needle Punching Machines: Essential for mechanically entangling fibers through the needle punching process.

Applications of Nonwoven Fabrics

Nonwoven fabrics find a wide range of applications across various industries due to their versatile nature and unique properties. Let’s explore some of the key uses of nonwovens in medical, automotive, and agricultural sectors, and discuss the advantages they offer over traditional woven fabrics.

Medical Sector

Nonwoven fabrics play a crucial role in the medical industry, where they are used for making surgical masks, gowns, drapes, and other medical textiles. These fabrics offer excellent barrier protection against bacteria and viruses, making them ideal for healthcare settings. The soft texture of nonwovens also ensures comfort for patients and healthcare professionals.

Automotive Industry

In the automotive sector, nonwoven fabrics are utilized for various applications such as car interiors, headliners, carpets, and engine components. These fabrics provide sound insulation, impact resistance, and thermal insulation, contributing to the overall comfort and safety of vehicles. Additionally, nonwovens are lightweight and cost-effective, making them a preferred choice for automotive manufacturers.

Agricultural Sector

Nonwoven fabrics are increasingly being used in the agricultural sector for crop protection, weed control, and soil stabilization. These fabrics help in conserving moisture, controlling temperature, and preventing the growth of weeds, thereby improving crop yield and quality. Nonwovens also offer UV resistance and biodegradability, making them environmentally friendly alternatives to traditional materials.

Advantages of Nonwovens over Traditional Fabrics

- Nonwoven fabrics are cost-effective and efficient in terms of production.

- They offer superior strength, durability, and flexibility compared to woven fabrics.

- Nonwovens can be designed to have specific properties such as absorbency, liquid repellency, and breathability.

- These fabrics are easy to customize and can be tailored to meet the requirements of different applications.

- Nonwovens are lightweight, making them suitable for applications where weight is a critical factor.

Sustainability in Nonwoven Fabric Production

Nonwoven fabric production, like any manufacturing process, has an impact on the environment. It is crucial to analyze this impact and explore ways to make the production of nonwoven fabrics more sustainable.When it comes to sustainability in nonwoven fabric production, several factors come into play. These include resource consumption, energy usage, waste generation, and the use of chemicals in the production process.

By understanding and addressing these factors, the industry can move towards a more eco-friendly approach.

Environmental Impact of Nonwoven Fabric Manufacturing

- Nonwoven fabric production consumes a significant amount of resources, such as water and raw materials.

- The energy used in the manufacturing process contributes to carbon emissions and overall environmental degradation.

- Waste generation, including the disposal of byproducts and scrap materials, poses a challenge for sustainability.

- The use of chemicals in the production of nonwoven fabrics can have negative effects on the environment if not managed properly.

Sustainability of Different Types of Nonwovens

- Some nonwoven fabrics are inherently more sustainable due to their production process, which may require less energy or fewer resources.

- Recycled nonwovens, made from post-consumer or post-industrial waste, offer a more sustainable alternative to virgin materials.

- Biodegradable nonwovens break down naturally over time, reducing their impact on the environment compared to non-biodegradable options.

Innovative Approaches for Eco-Friendly Nonwoven Production

- Implementing closed-loop systems to minimize waste and maximize resource efficiency in production.

- Exploring alternative energy sources, such as renewable energy, to power nonwoven fabric manufacturing facilities.

- Developing and using eco-friendly chemicals and dyes in the production process to reduce environmental harm.

- Investing in research and development to discover new sustainable materials and production techniques for nonwoven fabrics.

Textiles and Nonwovens

Textiles and nonwovens are both materials used in the production of various goods, but they differ in terms of structure and properties.

Differentiation between Textiles and Nonwovens

- Textiles are typically made from yarns that are woven or knitted together to form a fabric, whereas nonwovens are made directly from fibers that are bonded together without weaving or knitting.

- Nonwovens are made through processes like needle punching, spunbonding, or meltblowing, resulting in a structure that is more random and less uniform compared to textiles.

- Textiles often have a higher tensile strength and durability due to the interlocking nature of woven or knitted fibers, while nonwovens may have varying degrees of strength depending on the bonding method used.

Categorization of Nonwovens in the Textile Industry

Nonwovens are considered a separate category within the broader textile industry, known for their versatility and wide range of applications.

They are used in various sectors such as healthcare, automotive, construction, and agriculture, offering unique properties and performance characteristics that differ from traditional textiles.

Advantages and Limitations of Nonwovens

- Advantages:

- Nonwovens are often more cost-effective to produce than textiles due to their simpler manufacturing processes.

- They can be engineered to have specific properties such as absorbency, liquid repellency, or breathability, making them suitable for specialized applications.

- Nonwovens are lightweight, flexible, and can be designed to be biodegradable or recyclable, contributing to sustainability efforts.

- Limitations:

- Nonwovens may have lower tensile strength and durability compared to textiles, limiting their use in high-stress applications.

- They may lack the aesthetic appeal of woven or knitted fabrics, making them less desirable for certain consumer products.

- Nonwovens can be challenging to recycle or reuse due to the bonding methods used in their production.

Conclusion

As we wrap up our discussion on Nonwoven fabric types and uses, we hope you’ve gained a deeper understanding of this fascinating textile realm. Whether you’re drawn to the sustainability aspect or intrigued by the diverse applications, nonwoven fabrics continue to pave the way for innovative solutions in the modern world.

FAQ Resource

What are the key differences between spunbond, meltblown, and needle-punched nonwovens?

Spunbond is known for its strength, meltblown for filtration properties, and needle-punched for durability.

How are nonwoven fabrics environmentally friendly compared to traditional textiles?

Nonwovens require less energy and water in production and are often recyclable, reducing environmental impact.

What are some unique applications of nonwoven fabrics in the automotive industry?

Nonwovens are used for insulation, noise reduction, and reinforcement in automotive components.