Embark on a journey into the world of nonwoven fabrics for medical use, where science meets innovation to create groundbreaking solutions in healthcare. From surgical masks to infection control, these fabrics hold the key to a safer and more efficient medical industry.

Let’s dive deeper into the realm of nonwoven fabrics and discover the secrets behind their widespread adoption in the medical field.

Introduction to Nonwoven Fabrics for Medical Use

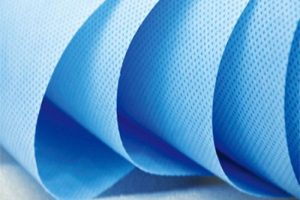

Nonwoven fabrics are materials composed of fibers bonded together through various processes, such as heat, chemicals, or mechanical techniques, without weaving or knitting. These fabrics are widely used in the medical field due to their unique characteristics that make them suitable for various applications.

Composition and Characteristics of Nonwoven Fabrics

Nonwoven fabrics used in medical applications are typically made from synthetic polymers like polypropylene, polyester, or polyethylene. These fabrics can also be produced from natural fibers like cotton or cellulose. The key characteristics that make nonwoven fabrics ideal for medical use include:

- High absorbency: Nonwoven fabrics can quickly absorb liquids, making them suitable for wound dressings and medical wipes.

- Breathability: These fabrics allow air circulation, reducing the risk of skin irritation and promoting faster healing.

- Barrier properties: Nonwoven fabrics can act as a barrier against bacteria and other contaminants, helping to maintain a sterile environment in medical settings.

- Softness and comfort: These fabrics are gentle on the skin, making them ideal for use in medical apparel, such as surgical gowns and masks.

Common Medical Products Using Nonwoven Fabrics

Nonwoven fabrics are extensively used in a wide range of medical products, including:

- Surgical masks and gowns: Nonwoven fabrics are commonly used in the production of surgical masks and gowns due to their breathability and barrier properties.

- Wound dressings: The high absorbency of nonwoven fabrics makes them ideal for wound dressings, helping to maintain a clean and sterile environment.

- Medical wipes: Nonwoven fabrics are often used in medical wipes for cleaning and disinfecting surfaces in healthcare settings.

- Disposable bed sheets and covers: These fabrics are used in disposable bed sheets and covers for their softness, comfort, and hygienic properties.

Advantages of Nonwoven Fabrics in Medical Settings

Nonwoven fabrics offer numerous advantages over traditional woven fabrics when used in medical settings. These advantages include superior performance, enhanced durability, and cost-effectiveness, all of which contribute to infection control in healthcare settings.

Performance and Durability

Nonwoven fabrics are specifically designed to meet the rigorous demands of medical applications. They are engineered to provide high levels of protection, strength, and barrier properties, making them ideal for use in surgical gowns, face masks, and other protective apparel. Unlike woven fabrics, nonwoven fabrics do not unravel or fray, ensuring a consistent level of protection throughout their use. Additionally, nonwoven fabrics can be manufactured with specific properties such as liquid resistance, breathability, and antimicrobial properties, further enhancing their performance in medical settings.

Cost-effectiveness

Nonwoven fabrics are cost-effective alternatives to traditional woven fabrics due to their efficient manufacturing process and lower material waste. The production of nonwoven fabrics involves fewer steps and less material compared to woven fabrics, resulting in reduced production costs. Additionally, nonwoven fabrics are lightweight and disposable, eliminating the need for costly cleaning and maintenance associated with reusable woven fabrics. This cost-effectiveness makes nonwoven fabrics a practical choice for healthcare facilities looking to maintain high levels of protection without exceeding their budget.

Infection Control

Nonwoven fabrics play a crucial role in infection control in healthcare settings. The barrier properties of nonwoven fabrics help prevent the transmission of pathogens between patients, healthcare workers, and the environment. Nonwoven fabrics used in surgical drapes, gowns, and masks act as a protective barrier against blood, bodily fluids, and other potentially infectious materials, reducing the risk of cross-contamination. Additionally, nonwoven fabrics can be treated with antimicrobial agents to enhance their ability to inhibit the growth of bacteria and viruses, further enhancing infection control measures in healthcare settings.

Manufacturing Process of Nonwoven Fabrics for Medical Use

Nonwoven fabrics for medical use are manufactured through various methods to ensure their quality and effectiveness in medical applications.

Spunbond Method

The spunbond method involves extruding polymer granules to form continuous filaments. These filaments are then laid onto a conveyor belt, bonded together through heat and pressure, and cooled to create a nonwoven fabric with high strength and durability.

Meltblown Method

In the meltblown method, polymer resin is melted and extruded through tiny nozzles to create microfibers. These microfibers are then blown onto a collector screen, forming a fine mesh of randomly oriented fibers. The fibers are then bonded together through heat or chemicals to produce a nonwoven fabric with excellent filtration properties.

Spunlace Method

The spunlace method involves using high-pressure water jets to entangle fibers and create a fabric. This process results in a softer and more fabric-like material, making it suitable for medical applications requiring comfort and breathability.

Needle Punching Method

In the needle punching method, barbed needles are used to mechanically interlock fibers and create a fabric. This process is commonly used to produce nonwoven fabrics with high bulk and resilience, making them ideal for medical applications requiring absorbency and cushioning.

Importance of Quality Control Measures

Quality control measures during the production of nonwoven fabrics for medical use are crucial to ensure the fabrics meet the required standards for safety and performance. These measures involve monitoring raw materials, manufacturing processes, and final products to detect any defects or inconsistencies that may affect the quality of the fabric.

Regulations and Standards

The production of nonwoven fabrics for medical use is governed by various regulations and standards to ensure the safety and efficacy of the products. Regulatory bodies such as the FDA and ISO have established guidelines that manufacturers must adhere to in the production of medical textiles to guarantee their quality and suitability for healthcare settings.

Applications of Nonwoven Fabrics in Medical Devices

Nonwoven fabrics play a crucial role in the production of various medical devices, enhancing their performance and safety. Let’s delve into how nonwoven fabrics are utilized in the creation of surgical masks, gowns, drapes, and other innovative medical devices.

Production of Surgical Masks, Gowns, and Drapes

Nonwoven fabrics are extensively used in the manufacturing of surgical masks, gowns, and drapes due to their excellent barrier properties. These fabrics provide protection against fluids, bacteria, and other contaminants, ensuring a safe and sterile environment during medical procedures. The lightweight and breathable nature of nonwoven fabrics also make them comfortable for healthcare professionals to wear for extended periods.

- Surgical Masks: Nonwoven fabrics are the primary material used in the production of surgical masks, providing filtration against airborne particles and preventing the spread of infectious diseases.

- Surgical Gowns: Nonwoven fabrics are used to create disposable surgical gowns, offering protection against fluids and contaminants during surgical procedures.

- Surgical Drapes: Nonwoven fabrics are integral in the production of surgical drapes, creating a sterile barrier between the patient and the surgical field.

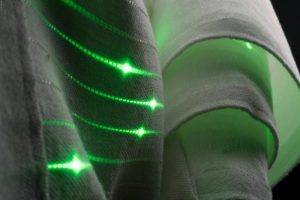

Innovative Medical Devices Utilizing Nonwoven Fabrics

Nonwoven fabrics are not limited to traditional medical devices but also play a crucial part in innovative medical technologies. For example, nonwoven fabrics are used in advanced wound dressings, drug delivery systems, and implantable medical devices. These fabrics provide a versatile platform for incorporating various functionalities to enhance the performance of these devices.

- Advanced Wound Dressings: Nonwoven fabrics with specific properties, such as moisture management and antibacterial effects, are used in advanced wound dressings to promote healing and prevent infections.

- Drug Delivery Systems: Nonwoven fabrics can be engineered to serve as drug delivery systems, allowing controlled release of medications for targeted treatment.

- Implantable Medical Devices: Nonwoven fabrics are utilized in the construction of implantable medical devices, providing biocompatibility and support for tissue integration.

Enhancing Performance and Safety of Medical Devices

Nonwoven fabrics contribute significantly to the performance and safety of medical devices by offering key advantages such as breathability, flexibility, and barrier protection. These fabrics help in maintaining a sterile environment, preventing infections, and improving patient outcomes in various medical settings.

- Breathability: Nonwoven fabrics allow air and moisture vapor to pass through, ensuring comfort for patients and healthcare professionals wearing medical devices for extended periods.

- Flexibility: Nonwoven fabrics can be tailored to specific requirements, allowing for flexibility in design and functionality of medical devices.

- Barrier Protection: Nonwoven fabrics provide an effective barrier against fluids, contaminants, and microorganisms, reducing the risk of cross-contamination and ensuring the safety of both patients and healthcare providers.

TEXTILES AND NONWOVENS

Textiles and nonwoven fabrics are both materials used in various industries, but they have distinct characteristics that set them apart.Textiles are traditionally woven or knitted fabrics made from yarn or thread, where the fibers are interlaced to form a stable structure. On the other hand, nonwoven fabrics are made by bonding or felting fibers together, without the need for weaving or knitting.

This process results in a fabric that is durable, cost-effective, and versatile.Nonwoven fabrics play a significant role as a subset of textiles in industries such as automotive, construction, agriculture, and filtration. In automotive applications, nonwovens are used for insulation, noise reduction, and upholstery. In construction, they are used for geotextiles, roofing materials, and insulation. In agriculture, nonwovens are used for crop protection, landscaping, and soil stabilization.

Additionally, nonwoven fabrics are extensively used in filtration applications for air, water, and industrial processes.

Industries Beyond Medical Applications

Nonwoven fabrics find extensive use in industries beyond medical applications due to their unique properties and versatility.

- Automotive: Nonwoven fabrics are used in car interiors for sound insulation, carpeting, and upholstery.

- Construction: Nonwovens are utilized in geotextiles for soil stabilization, drainage systems, and erosion control.

- Agriculture: Nonwoven fabrics are employed in crop protection, landscaping, greenhouse coverings, and soil erosion prevention.

- Filtration: Nonwovens are crucial in air filters, water filtration systems, and industrial liquid filtration processes.

- Personal Care: Nonwoven fabrics are used in baby diapers, feminine hygiene products, wipes, and adult incontinence products.

Ultimate Conclusion

As we wrap up our exploration of nonwoven fabrics for medical use, it’s clear that these materials are not just fabric – they are a cornerstone of modern healthcare. With their unique properties and versatile applications, nonwoven fabrics continue to revolutionize the way we approach medical devices and infection control.

Commonly Asked Questions

What sets nonwoven fabrics apart from traditional woven fabrics in medical use?

Nonwoven fabrics are known for their superior strength, breathability, and liquid resistance, making them ideal for medical applications where hygiene and durability are crucial.

Are there specific regulations governing the production of nonwoven fabrics for medical use?

Yes, regulatory bodies such as the FDA and ISO have stringent guidelines to ensure the quality and safety of nonwoven fabrics used in medical devices and products.

Can nonwoven fabrics be recycled or are they single-use only?

While some nonwoven fabrics are designed for single-use to maintain sterility, advancements in technology have allowed for the development of recyclable nonwoven materials for certain medical applications.