Dive into the world of Textile and nonwoven innovations where traditional fabrics meet cutting-edge technology, creating a tapestry of endless possibilities. From eco-friendly practices to advanced materials, this topic explores the evolution of textiles and nonwovens in various industries.

TEXTILES AND NONWOVENS

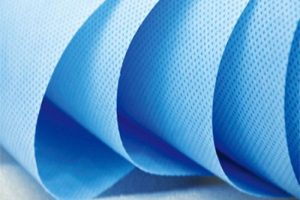

Textiles and nonwovens are two distinct materials used in various industries for different purposes. While textiles are woven or knitted fabrics made from natural or synthetic fibers, nonwovens are manufactured by bonding fibers together through mechanical, chemical, or thermal processes without the need for weaving or knitting.

Differences between Textiles and Nonwovens

- Textiles are woven or knitted, while nonwovens are bonded together without weaving or knitting.

- Textiles are typically more durable and have a higher tensile strength compared to nonwovens.

- Nonwovens are often used for disposable applications due to their lower cost of production.

Key Characteristics of Textiles and Nonwovens

- Textiles are breathable, comfortable, and have good drapability, making them suitable for clothing and home textiles.

- Nonwovens are versatile, lightweight, and can be engineered for specific functionalities like absorbency, liquid repellency, or filtration.

- Both textiles and nonwovens can be produced in a wide range of colors, patterns, and finishes to meet various design requirements.

Applications of Textiles and Nonwovens in Various Industries

- Textiles are commonly used in the fashion industry for clothing, accessories, and footwear due to their aesthetic appeal and comfort.

- Nonwovens find applications in healthcare for surgical gowns, face masks, and wound dressings due to their barrier properties and absorbency.

- Automotive industry utilizes textiles for car interiors, seat covers, and upholstery, while nonwovens are used for sound insulation and filtration applications.

Textile Innovations

In the ever-evolving textile industry, innovations play a crucial role in pushing the boundaries of what is possible. From advanced materials to cutting-edge technology, the landscape of textile manufacturing is constantly changing to meet the demands of a modern world.

Advanced Materials in Textile Production

- Carbon Fiber: Known for its high strength-to-weight ratio, carbon fiber is increasingly being used in textiles to create durable and lightweight products.

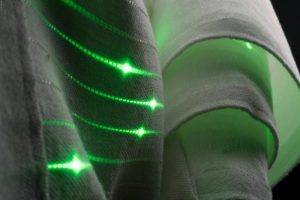

- Smart Fabrics: These textiles are embedded with sensors and other electronic components to provide functionalities like temperature regulation, moisture management, and even health monitoring.

- Recycled Fibers: With a growing focus on sustainability, recycled fibers made from materials like plastic bottles or old clothing are being used to create eco-friendly textiles.

Technology Shaping the Future

- 3D Printing: This technology allows for the creation of intricate textile designs and structures that were previously impossible to achieve with traditional methods.

- Nanotechnology: By manipulating materials at the nanoscale, nanotechnology is revolutionizing the properties of textiles, making them water-repellent, stain-resistant, or even self-cleaning.

- Automation: Robotics and AI are increasingly being integrated into textile manufacturing processes, leading to greater efficiency, precision, and customization in production.

Nonwoven Innovations

Nonwoven technologies have seen significant advancements in recent years, offering a wide range of applications and benefits. These innovative materials are reshaping the textile industry and paving the way for sustainable practices.Nonwovens are being used in sustainable practices due to their efficient production process that minimizes waste and energy consumption. They are often made from recycled materials, further reducing the environmental impact of textile production.

Additionally, nonwoven materials are biodegradable, making them a more eco-friendly alternative to traditional fabrics.

Performance Comparison

- Nonwoven materials are known for their lightweight and breathable properties, providing comfort and flexibility in various applications.

- Traditional fabrics, on the other hand, may be heavier and less versatile, limiting their performance in certain uses.

- Nonwovens also offer superior durability and resistance to wear and tear compared to some conventional textiles.

Sustainability Comparison

- Modern nonwoven materials are often produced using eco-friendly processes that reduce water and energy consumption.

- Traditional fabrics may involve extensive use of chemicals and water in their manufacturing, contributing to pollution and waste.

- Nonwovens can be recycled or composted at the end of their lifecycle, promoting a circular economy and reducing landfill waste.

Sustainability in Textiles and Nonwovens

As the demand for sustainable products continues to rise, the textile and nonwoven industries are also shifting towards eco-friendly practices to reduce their environmental impact.

Eco-Friendly Practices in Production

- Implementing water-saving technologies to reduce water consumption during manufacturing processes.

- Using renewable energy sources such as solar or wind power to power production facilities.

- Optimizing supply chain logistics to minimize carbon emissions from transportation.

Recycled Materials for Sustainable Textiles

- Utilizing recycled polyester fibers from plastic bottles to create fabrics for clothing and home textiles.

- Incorporating recycled cotton fibers from post-consumer or post-industrial waste into new textile products.

- Exploring innovative ways to recycle and repurpose textile waste to minimize landfill contribution.

Impact of Sustainable Innovations

- Reduction of overall carbon footprint in the textile and nonwoven industries through sustainable practices.

- Enhanced brand reputation and consumer trust due to commitment to environmental stewardship.

- Encouraging a shift towards circular economy models, where materials are reused and recycled to create a closed-loop system.

Closing Summary

As we wrap up our exploration of Textile and nonwoven innovations, it’s clear that sustainability, technology, and creativity are driving forces in shaping the future of fabric production. The fusion of tradition and innovation promises an exciting journey ahead in the textile and nonwoven industries.

Question Bank

What are the key differences between textiles and nonwovens?

Textiles are woven or knitted fabrics, while nonwovens are made directly from fibers without weaving or knitting.

How is technology influencing the future of textile manufacturing?

Technology is revolutionizing textile manufacturing through automation, digital printing, and smart textiles.

What role do nonwovens play in sustainable practices?

Nonwovens are used in sustainable practices like filtration, medical textiles, and geotextiles due to their versatility and eco-friendly nature.